CETRIS® PDB

Technical data sheet for download

CETRIS® PDB

Cement bonded particleboard calibrated by sanding with the size of 1 250 x 625 mm (including the tongue) for dry floor technologies.

The adjustment reduces thickness tolerance to +/- 0.3 mm. The following thicknesses are offered as standard: 16, 18, 20, 22, 24, 26, 28 mm (on the basis of agreement 30-32-34-36mm). There is a tongue and groove on the perimeter of the boards and they are to be laid over beams or used in restoration of floors.

Technical specifications:

| Basic size: | 1 250 x 625 mm (Including tongue) |

|---|---|

| Board thickness: | 16-18-20-22-24-26-28 mm (on the basis of agreement 30-32-34-36 mm) |

| Bulk density: | 1 150 - 1 500 kg/m3 |

| Service: | milled edges, tongue and groove, sanding |

| Thickness tolerance: | +-0,3 mm |

| Surface finish: | without surface finish |

Suitable for systems:

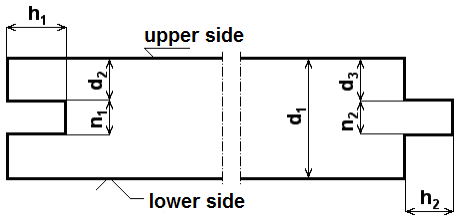

| d1 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| n2 | 5,5 | 5,5 | 5,5 | 5,5 | 7,0 | 7,0 | 7,0 |

| n1 | 6,0 | 6,0 | 6,0 | 6,0 | 8,0 | 8,0 | 8,0 |

| d2 | 5,0 | 6,0 | 7,0 | 8,0 | 8,0 | 9,0 | 10,0 |

| d3 | 5,25 | 6,25 | 7,25 | 8,25 | 8,5 | 9,5 | 10,5 |

| h1 | 10,0 | 10,0 | 10,0 | 10,0 | 10,0 | 10,0 | 10,0 |

| h2 | 8,5 | 8,5 | 8,5 | 8,5 | 8,5 | 8,5 | 8,5 |

| Tloušťka | CETRIS® PDB | Přibližná hmotnost | Přibližná hmotnost desky | Počet desek na paletě | Celková přibližná hmotnost desek na paletě |

|---|---|---|---|---|---|

| mm | Kč/m2 | kg/m2 | kg/ks | ks | kg |

| 16 | -- | 23,2 | 18,1 | 50 | 935 |

| 18 | -- | 26,1 | 20,4 | 45 | 948 |

| 20 | -- | 29,0 | 22,7 | 40 | 938 |

| 22 | -- | 31,9 | 24,9 | 35 | 902 |

| 24 | -- | 34,8 | 27,2 | 35 | 982 |

| 26 | -- | 37,7 | 29,5 | 30 | 915 |

| 28 | -- | 40,6 | 31,7 | 30 | 981 |

| 30 | -- | 43,5 | 34,0 | 29 | 1016 |

| 32 | -- | 46,4 | 36,3 | 27 | 1010 |

| 34 | -- | 49,3 | 38,5 | 25 | 993 |

| 36 | -- | 52,2 | 40,8 | 23 | 968 |

Všechny uvedené ceny jsou bez DPH s odběrem ve výrobním závodě CETRIS Hranice. Dodací a platební podmínky se řídí Všeobecnými obchodními a dodacími podmínkami CIDEM Hranice, a. s. platnými pro rok 2025.

CETRIS® board properties

Cement bonded particleboards CETRIS® combine favourable features of cement and wood.

They are lighter than conventional cement-fibre boards, their strength and resistance against weather conditions, frost and mould ranks them higher than cement bonded chipboards or gypsum plasterboards.

- 0%Wood chips

- 0%Binder (cement)

- 0%Water

- 0%Hydration additives

Composition of the board in weight percentage

CETRIS® boards are:

Fire resistant

CETRIS® cement-bonded particleboards without surface treatment are fire-resistant and their classification according to the reaction to fire class of the European standard EN... is A2... d0 non-flammable. CETRIS® cement-bonded particleboards with surface treatment are classified according to the reaction to fire class of the European standard EN.

Environment friendly

CETRIS® cement bonded particleboards are ecological and environment friendly. They contain no hazardous substances such as asbestos and formaldehyde and they are resistant to petrol and oils.

Frost-resistant

CETRIS® cement bonded particleboards are frost resistant, tested successfully by 100 freezing-defrosting cycles pursuant to ČSN EN 1328 standard.

Weather resistant

CETRIS® cement bonded particleboards is the best material for wet rooms and weather-exposed exteriors for its excellent humidity resistance.

Hygienic harmless

CETRIS® boards are hygienic harmless, odourless and contain no hazardous substances.

Perfect sound barrier

CETRIS® boards provide for acoustic insulation (sound transmission loss 30 – 35 dB).

Fungi and mould resistant

Moulds are not formed on the board surface thanks to the CETRIS® board resistance to humidity.

Insect resistant

CETRIS® cement bonded particleboards are absolutely insect resistant thanks to their cement content.

Services and surface finish

Cement bonded CETRIS® particleboards can be processed by all commonly available wood processing machines. The professional treatment of boards requires tungsten carbide tipped tools. The boards may be cut, drilled, milled and grinded. The boards may be attached to structures by screwing, or riveting. Alternatively, CETRIS® board may be attached to a load-bearing structure by gluing or with clamps. Both methods are used, in particular, to attach boards in suspended vented facades - see Facade systems.

CETRIS® boards can be cut in lengthwise, lateral or crosswise direction according to the customer requirements. The boards are always cut from the basic production size of 3350x1250 mm using special equipment. Minimum possible dimensions of cut rectangular sizes are 50x50 mm. Maximum possible dimensions of cut rectangular sizes are 1225x3325 mm.

The boards can be delivered delivered with drilled holes, including countersinks, based on the drill plan submitted by the customer.

Full-size machine sanding is performed in the context of manufacture of floor boards CETRIS® PDB for the reason of reduction of thickness tolerance to +- 0.3 mm.

On customer's request we provide side edge of CETRIS® cement bonded particleboards with milling of semi-tongue, groove and tongue or chamfered edge.

Application of surface finish on CETRIS® cement bonded particleboards must respect principles laid down in the relevant technical and assembly procedures. For recommended materials and principles of application please visit here.

|

Detailed information: |

Download information |

|

Regulation for surface finish applications: |

Download information |

Packaging, storage, handling and parameters of dispatched CETRIS boards®

CETRIS® cement bonded particleboards are placed on wooden transport pallets for forklift handling. The boards are fixed to the platform using a banding in a crosswise manner; longitudinal banding is possible upon the customer's request.

The boards are protected against weather conditions with a PE foil packaging. This packaging type does not meet conditions for long-term weather exposure by open-air storage.

CETRIS® cement bonded particleboards should be stored in roofed, dry space to prevent moisture absorption by the boards before installation in the building structure.

When storing boards without surface finish pallets of the same size can be stacked. Pallets with boards with surface finish cannot be stacked.

CETRIS® boards should be placed on a pallet for handling. If stored differently the boards should be handled vertically. Also manual transport should be carried out with the boards in vertical position.

|

Detailed information: |

Download information |

Board dealers

Looking for our boards? Not knowing where to buy them? Find the nearest dealer.

Information and training courses

Needing more information about our boards? Try our training course or call us.